surface grinding machine pdf

Pdf 7 MB BLOHM PROFIMAT MT Product Brochure Download. The work piece moves v at 15 mmin.

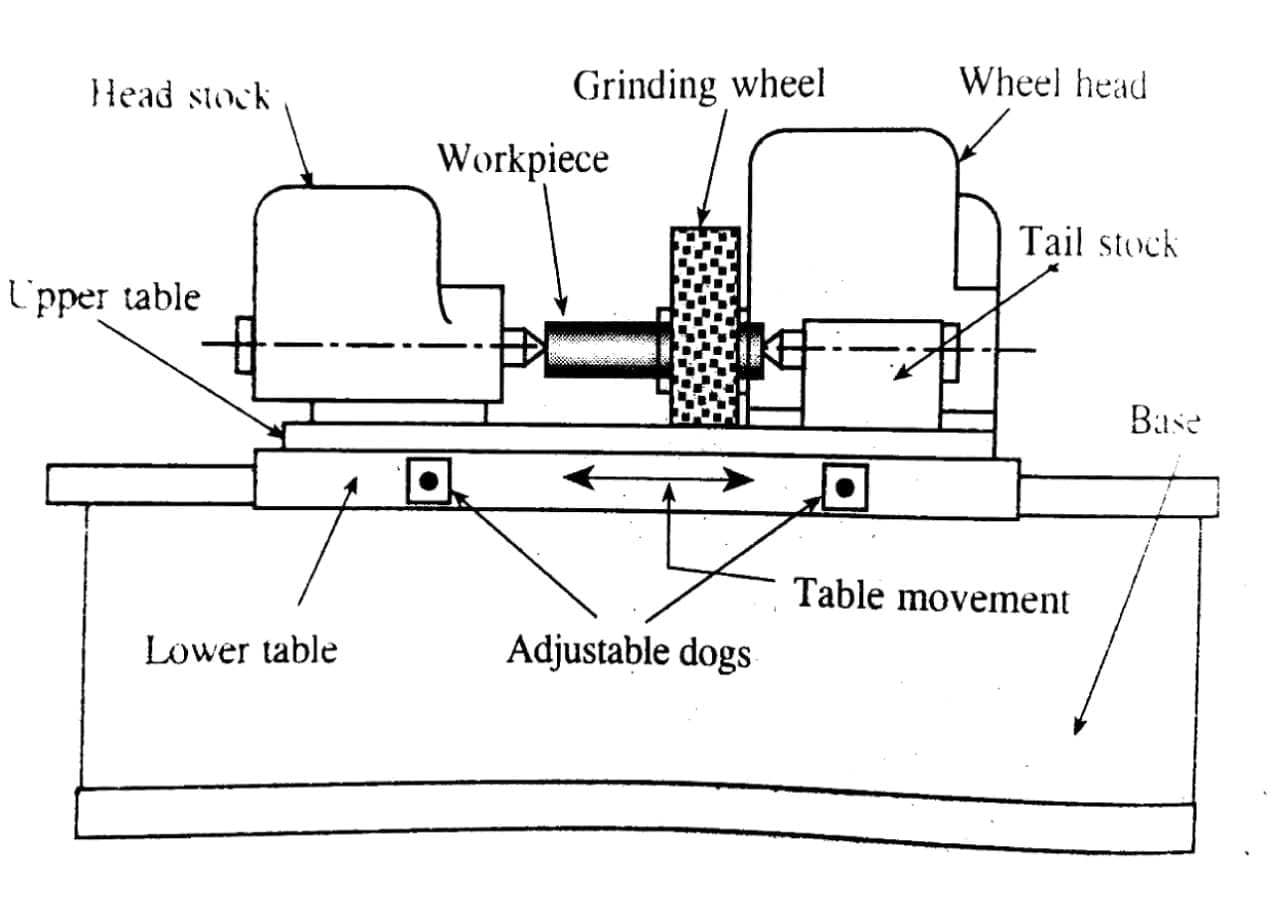

Horizontal Spindle Surface Grinding Machine With Reciprocating Table Download Scientific Diagram

Komang Candra Dwimantara Nim.

. The only parts purchased were pulleys tw o Myford gear wheels 30 and 60 teeth two bearing blocks and elevating screw hand-wheel. 13During wet grindingthe nozzles cannot be adjusted when the wheel spindle is rotating. It is also called an abrasive machining process where abrasives are placed on the surface and corners of the grinding wheel so as to do the finishing process with much more accuracy.

Table Travel mm 480 510 510 Max. Liebherr L514-790 Wheel Loader Service Repair Manual SN14000pdf. It is designed to be used as an adjunct to teaching Safety Procedures and to act as a reminder to users prior to machine use.

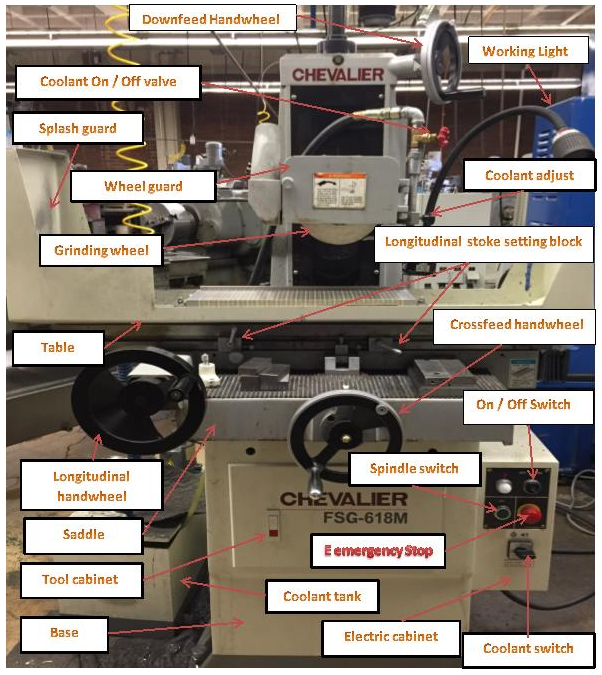

Steinmetz SAFETY OPERATING PROCEDURES Surface Grinder - Elliott Victoria DO NOT use this surface grinder unless you received training by a. Types of Grinding wheels. Types of surface grinding machines Tool and cutter grinder In grinding tools by hand a bench or pedastal type of grinder is used.

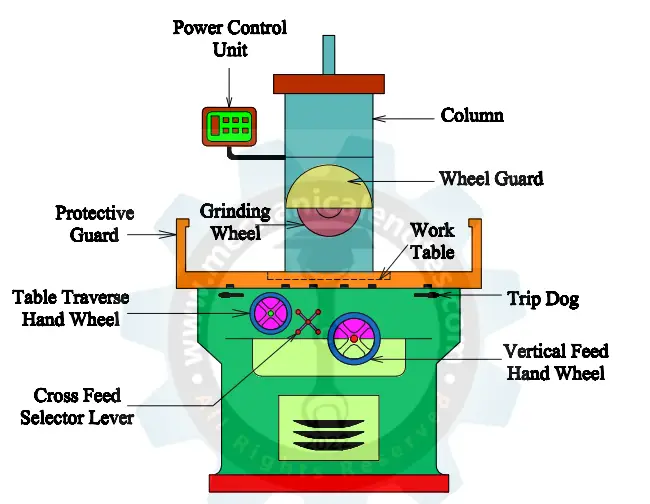

12When grindingbesides securely mounting the work pieceone should make sure no other object is placed on the machine. Cross Travel mm 178 250 250 Distance Between Table Surface and Spindle Center mm 360. It is a finishing process that uses a rotating abrasive wheel to smooth the flat surface of metallic or non-metallic materials to give them a more refined look or to attain a desired surface for a functional purpose.

Last review 02 March 2011 UofS Mech. Universal cylindrical surface grinder 3. Entire machine is fabricated in steel picked from scrap.

Production of flat surfaces. For sharpening miscellananeus cutters a universal type grinder is used. Ordinary grinding machines are widely used.

Centreless cylindrical surface. This system then removes the material to the level of the grinding surface and no further. 14When the work table is in motion or when the wheel spindle is rotatingthe work piece can not be moved or changed.

Turn on the machine power by turning the switch to the ON position. Advent of advanced grinding machines and grinding wheels has elevated the status of grinding to abrasive machining where high accuracy and surface finish as well as high material removal rate can be achieved even on an unhardened material. We are very happy with the performance of these machines and always recommend Alex to people who want high precision and maintenance free Surface Grinding Machines.

Building a Business When There Are No Easy. Shaping Planning Machines Shaping and planning are similar operations. Surface grinding is the most common of the grinding operations.

The motor has a power of 2 kW. Lock the dresser onto the bed by turning the magnetic chuck on. The chip thickness ratio r is 10.

The tool is hand held and moved across the face of the wheel continually to avoid excessive grinding in one spot. Creep feed grinding is an adaptation of surface grinding which introduces a moving stock material into the path of a rotating abrasive wheel. Horizontal spindle and reciprocating table type 2.

Broadly there are three different types of cylindrical grinding machine as follows. Cutting tools used in both operations are single-edge cutting tools to create a straight and flat surface. Machines in which grinding wheels are fitted and grinding is done such machines are called grinding machines.

Grinding energy u of 35 W-smm3. There are four different types of surface grinders. The machine should not be used to grind lumber plastic or other combustible materials.

The material is held in place while the grinding surface moves across or is lowered into the material. We have been using Alex Surface Grinders for over 25 years now and also been buying new machines from Alex on regular basis for our increase in production. The machine must not be installed in areas with explosive materials.

Rotary Table Grinding Machines. A surface Grinding Machine is a machine in which a grinding wheel is used as a cutting tool for removing the material from the surface of the workpiece. These machines are limited to low speeds due to their start-.

The grinding wheel rotates at 3600 rpm has a diameter D of 150 mm thickness b of 25 mm and c 5 grains per mm2. Determine the. The Hard Thing About Hard Things.

The bulk grinding wheel workpiece interaction as given in Figure 2 can be divided into the following. My outlay was under 6 including the cost of welding. I Made Pradnyana Artha Nim.

Plain centre type cylindrical grinder 2. Surface. Generally the grinding is finishing operation to show the high surface quality accuracy of the shape and dimension.

Notice the difference between Boringand Drilling. Precision Surface Grinding Machine Precision Surface Grinding Machine and Technology 0506 7HFK UHVHUYHV WKH ULJKW WR FKDQJH VSHFLILFDWLRQV DQG GHVLJQ FKDUDFWHULVWLFV ZLWKRXW SULRU QRWLFH Standard accessories K v o 2 Axes Crossfeed Set Up Grinding Cycle 1. These are called rough or snagging grinders.

Then press the green button to start the spindle. A grinding machine or grinder is an industrial power tool that uses an abrasive wheel for cutting or removing the m aterial. Wet grinding material that produce dust during the grinding process.

Surfaces may be straight tapered steps or profiled. The surface grinder is composed of an abrasive. SURFACE GRINDING MACHINE KGS 150 KGS 250 KGS818AHAHRAHD Picture shown with optional accessories PARAMETERS UNIT KGS 150 KGS 250 KGS818AHAHRAHD Working Surface of Table mm 150 x 450 200 x 460 200 x 460 Max.

It is a process of metal cutting by using a rotating abrasive whee l from the surface of the workpiece. Move the grinding wheel down using the vertical table handwheel until it barely makes contact with the dresser. Cylindrical grinding machine This machine is used to produce external cylindrical surface.

3 D Teknik Mesin What Is Surface Grinding Machines. Determine the grinding force and force per grain. Movable control panel.

Pdf 7 MB BLOHM PLANOMAT Product Brochure Download. Study of Machine Tools Grinding Machines Page 2 424 Surface grinding machines Surface grinding machines are employed to finish plain or flat surfaces horizontally vertically or at any angle. Interrupted cutting occurs in them subjecting the tool to an impact loading upon entry into the work.

Combustible liquids must not be used as a cutting liquid. F All machining was done on a ML7 lathe excepting the shaping of column and surface grinding. On the basis of their function they can be divided into two parts.

Grinding Machine Definition Parts Working Principle Operation Advantages Application Notes Pdf

Hydraulic Circuit For Surface Grinding Machine Explained In Details Engineering Arena

Grinding Machine Parts And Functions Mechanical Walkins

Guru Arjan Machine Tools Surface Grinder Machine Surface Grinding Machine Surface Grinding Machine Manufacturer

Chapter 5 Surface Grinder Manufacturing Processes 4 5

Muhammad Musa Muslimmuhammad313 Profile Pinterest

Types Of Surface Grinding Machine With Diagram Explained

14 Types Of Grinding Machines Working Diagram Pdf

243278011 Surface Grinding Report Title Universal Surface Grinding Introduction Surface Grinding Studocu

Everything You Need To Know About A Grinding Machine Studentlesson

Ajax Aj750h Surface Grinding Machine Used Machines Exapro

Horizontal Spindle Surface Grinding Machine With Reciprocating Table Download Scientific Diagram

Surface Grinding Machine Definition Parts Working Advantages Disadvantages Applications Pdf

M820 Manual Surface Grinding Machine Manual Grinding Machine Factory In China

Manual Surface Grinder Wheel Head Moving Surface Grinders Manufacturer From Faridabad